Recycled for lasting value

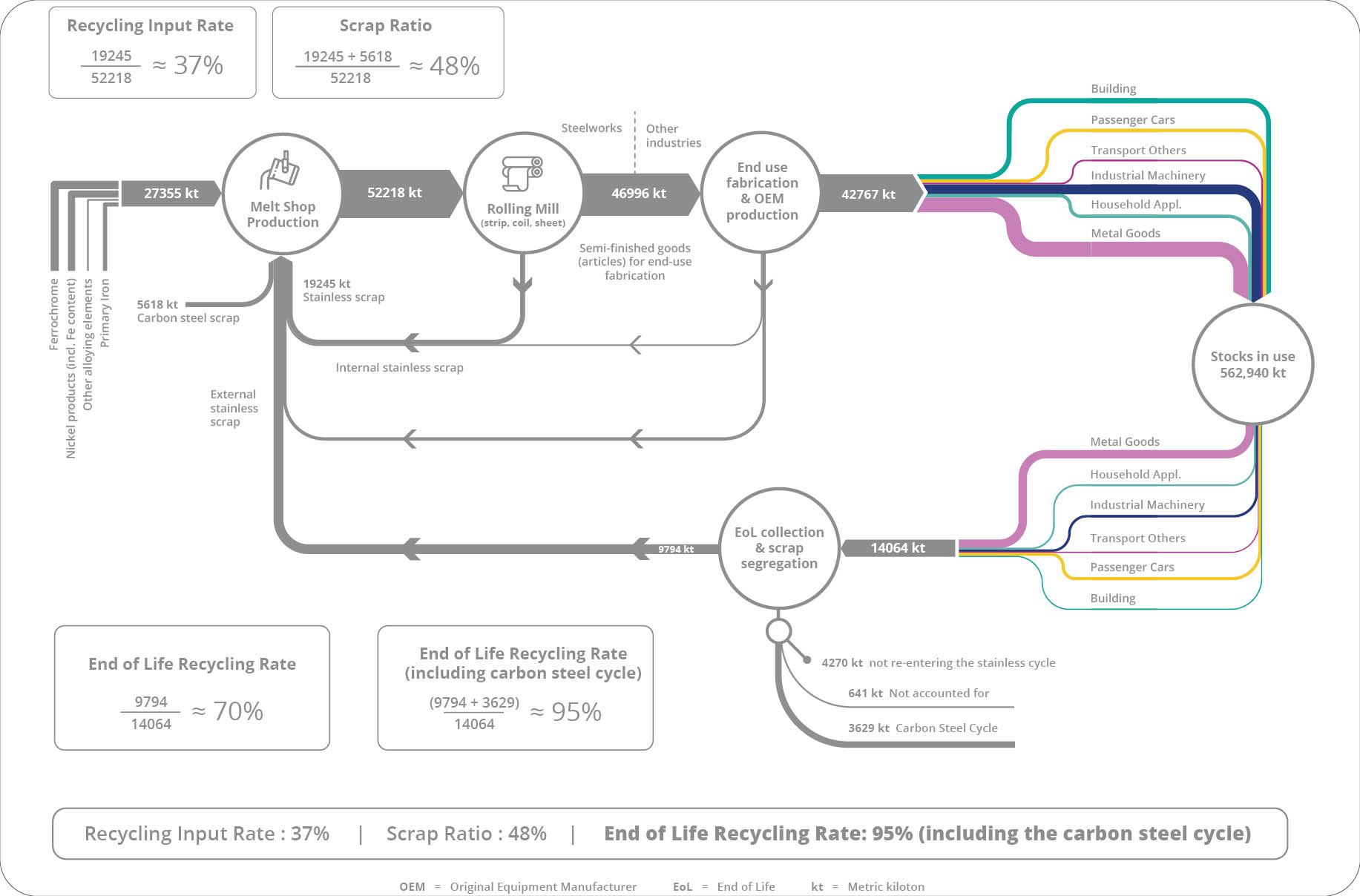

In under three minutes, this video shows stainless steels as a champion of recycling, with around 95% of end-of-life stainless steels being collected and recycled into new stainless steels without loss of quality. Durability and recyclability are two of the key contributions which stainless steels makes to sustainability.

Watch now