Introduction

It should be noted that within the stainless steels industry there are essentially two production systems, namely;

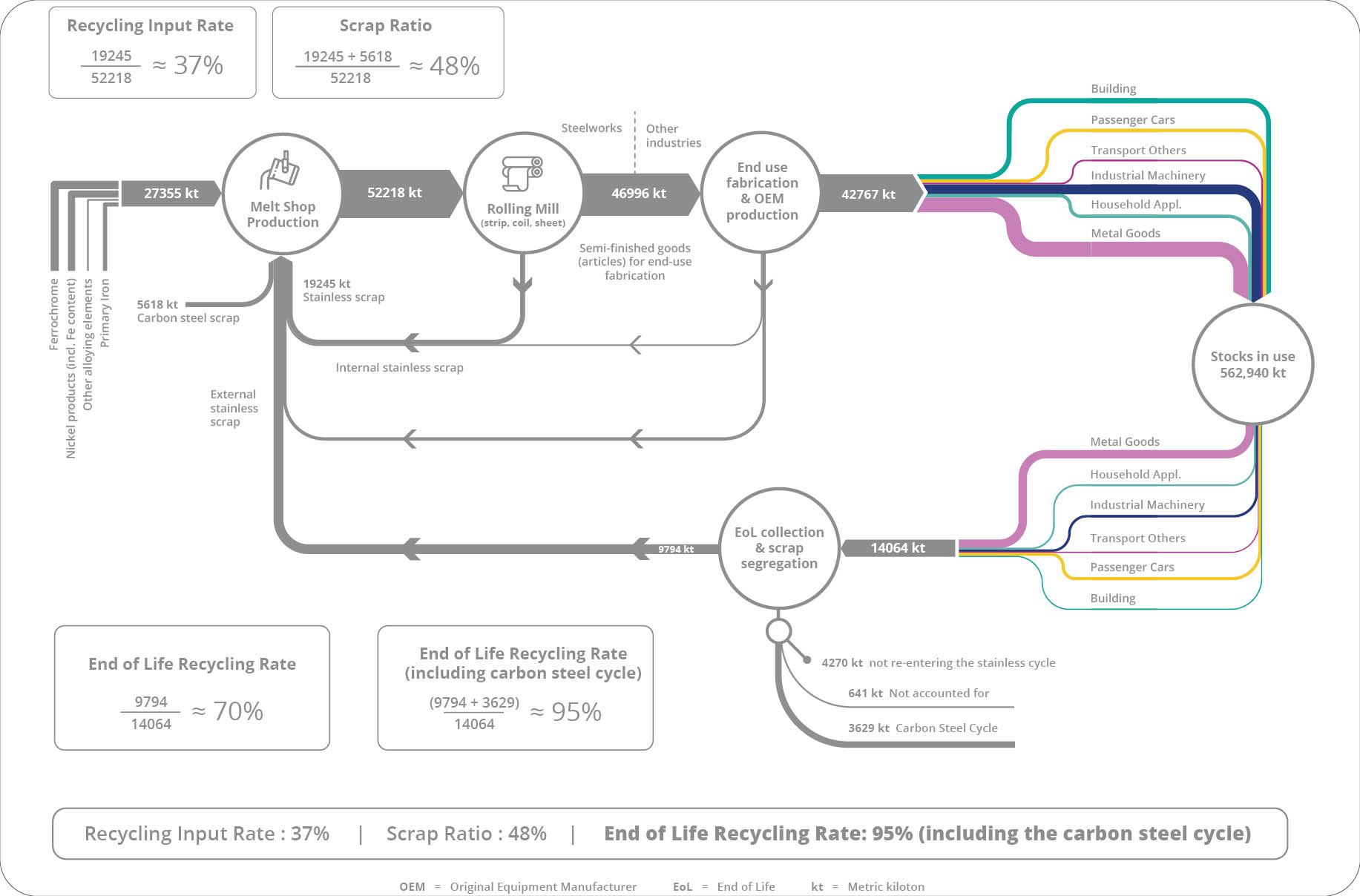

- The scrap-based production system in which the bulk of used raw materials are end-of-life stainless steels and/or similar alloy materials that are recycled to produce new stainless steels. This production system is aligned to geographical locations where the availability of end-of-life materials and scrap is high.

- The Nickel Pig Iron (NPI) production system in which the bulk of the Nickel units required for stainless steel production is not derived from stainless steel scrap, but from extracted Nickel ores which are converted into NPI. This production system is aligned to geographical locations where the availability of stainless steel scrap is low.

There is currently insufficient available end-of-life stainless steel scrap in all regions of the world to permit only scrap-based production to exist. Therefore these production routes will co-exist for the foreseeable future.